Management of the complete supply chain is a hard task; however, it may be partitioned into 5 predominant elements which we’re going to look at below.

1: Planning

One of the largest questions procurement groups want to invite is whether or not the company plans to fabricate items themselves or they may purchase ready-made items.

In the occasion that the employer manufactures completed merchandise, the subsequent query that arises is wherein will uncooked substances be sourced. Will it be from local, regional, or worldwide providers?

This query is likewise posed if the employer is shopping ready-made merchandise and passing them to the patron in a completed state. From wherein will those merchandises be obtained?

2: Sourcing

Following at the heels of the primary aspect is the second step which includes sourcing.

This step is one of the maximum essentials of the complete supply chain as it’s miles at this level that the largest value financial savings may be achieved.

Choose the proper supplier presenting the precise charge and who has the ability to supply required volumes in a well-timed style and you’ve struck gold.

Select an incompetent provider and this could have an effect on operations alongside the complete supply chain.

This manner may also encompass the want to now no longer simplest locate providers but examine and qualify them.

3: Inventory

Having numerous providers so that you can steady sufficient uncooked substances and or merchandise so that you can continue to be absolutely stocked up is extraordinarily critical. There are several instructions to be derived via way of means of analyzing shopping and supply chain control in 2020.

2020 verified the significance of having this aspect correct. According to RetailNext, 28% of surveyed groups suffered excessive shortages or even went out-of-inventory of positive key items. 56% of those organizations needed to renegotiate contracts.

The capacity to cautiously control stock and make certain that production schedules are in alignment with patron calls is as a good deal an ability as it’s miles an art.

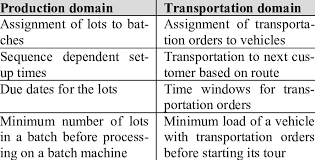

4: Production and Transportation

The subsequent critical aspect in supply chain control is production, warehouse, and transportation.

This detail of the delivery chain takes a study of what is wanted to make certain that the company is generating the ideal quantity of merchandise and that the product nice meets set-up standards.

This aspect additionally elements wherein the goods may be stored i.e. garage in warehouses in addition to transportation from stated depots to shops with the purpose to maintain the goods.

5: Return of Goods

What do you do whilst a client returns a product that’s defective? What is the protocol to address such an incident?

These questions are responded to withinside the very last aspect of the delivery chain ‘Return of Goods. Because client pride is extraordinarily critical, it’s miles vital that there be an actually described protocol surrounding the manner of the return.

The greater green the go back of defective product procedures the better your client pride ratings.

Conclusion

Knowing those 5 additives of deliver chain control makes it viable to expand powerful techniques to control your sports greater efficiently.

Supply chain control is so essential in any company’s backside line. And being capable of seeing how every hyperlink suits withinside the chain – how every stakeholder and provider performs a pivotal position withinside the normal chain – will provide you with the essential perception to make choices that gain all and sundry involved.

One of the primary steps to enhancing provider relationships is thru the mixing of modern provider control software programs together with that furnished via way of means of ProcurePort.